Fuel Injector Testing & Cleaning Service

We are now offering a Fuel Injector testing and cleaning service for most modern top feed fuel injectors (with the exception of Side feed, Diesel and DI systems)

With years of experience with testing and inspecting injectors In-house for several big “Tuning” Companies we have decided we should offer the service to our customers who are doing their own builds or having issues that could be down to injector running issues.

Injectors over time can get blocked and just deteriorate so makes good practice to get them at least checked especially if you are experiencing running problems, sudden higher consumption and if you are even looking at a new project and just want the injectors testing for peace of mind.

We are offering a service to check the injectors are working and balanced correctly right through to full cleaning and replacement of seals and filters as necessary.

Below is a video of a set of new injectors purchased from China which are very popular because of the cost. Reality is they can often ben poorly made and in this case we had one injector seized open that was pouring fuel into the cylinder as soon as the pump ran causing the engine to hyrolock and wreck a new build. Also you can clearly see how far out of balance the injectors actually are hence why testing is always advised on a new build or experiencing running issues.

A few Pounds spent now could cost save thousands later!

Our service includes the following:

-

Initial flow testing

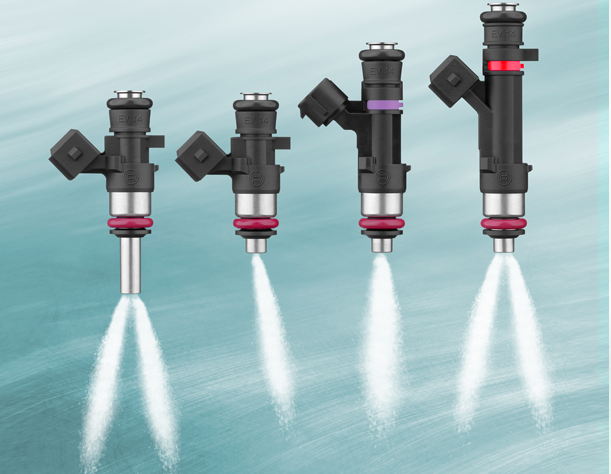

The first step in the process is initial flow testing. Flow testing includes inspection for leaks, Resistance testing, spray pattern, pulse operation, and flow rate verification. If your injectors are functioning properly and you selected 'Not Required Choice' on the order form, we will not clean them. This helps keep costs to the customer low and service times short!

-

Ultrasonic cleaning (If Selected)

After cleaning any dirt and lose particles off the body of the injectors we immerse the injectors in an ultrasonic cleaner and cleaning solution while simultaneously pulsing and back flushing them in order to help remove all debris and deposits from inside the injector.

-

Post-cleaning test

Once the injectors have been cleaned, we flow test the injectors again to ensure that they are all performing optimally.

-

Flow data sheet

You will receive a flow sheet which contains flow data from the initial test as well as the post-cleaning test.

-

Seal and filter replacement

We will replace all standard injector seals if necessary – (Please make sure you include the injector seals with the injectors so that we can match the seals that fit the vehicle) Many injectors also use an internal screen or ‘filter basket’ which we replace if necessary.

-

Pintle caps

Injector pintle caps are often in good condition and do not need to be replaced. If you have broken or missing pintle caps we can usually replace them. Some injectors have unique caps that may be special order and we will contact you if there will be extra cost associated with the pintle cap replacement.

Mailing Instructions Simply print out your sales invoice and put it in the package with your clean, dry, carefully packed fuel injectors (they should be packaged so that they don’t bang into each other and we require "ONLY" the injectors) Once we receive your injectors, we will begin the flow testing and/or cleaning process.

RETURN SHIPPING We use Royal Mail Priority service with insurance and tracking. All return shipping charges are the responsibility of the customer and paid for upon order of the service